General Cooling Recommendations for Partner-Cooled SuperNICs

IMPORTANT NOTES:

This section applies to 900-9X85E-00EX-MP0 SuperNIC.

The customer holds exclusive responsibility for the thermal design and for ensuring all board components never exceed their designated thermal operating limits.

The recommendations provided in this chapter are based on an air-cooled and liquid-cooled thermal design. For further information about NVIDIA’s air-cooled thermal design, please refer to your NVIDIA representative.

If the customer's environment has low or no airflow (e.g., liquid cooling) where the SuperNIC is to be installed, the customer must ensure proper cooling for all the other board components that are not covered by the recommendations of this chapter or in the product's thermal model. The customer must guarantee those components do not exceed their thermal operating limits as well.

The partner-cooled thermal solution dimensions exceed the OCP 3.0 specifications. The customer must ensure that the liquid solution is assembled after the card is inserted in the server.

Recommended torque values for the bracket screws: M2: 0.14-0.18 Nm. Use tool with Torx #5.

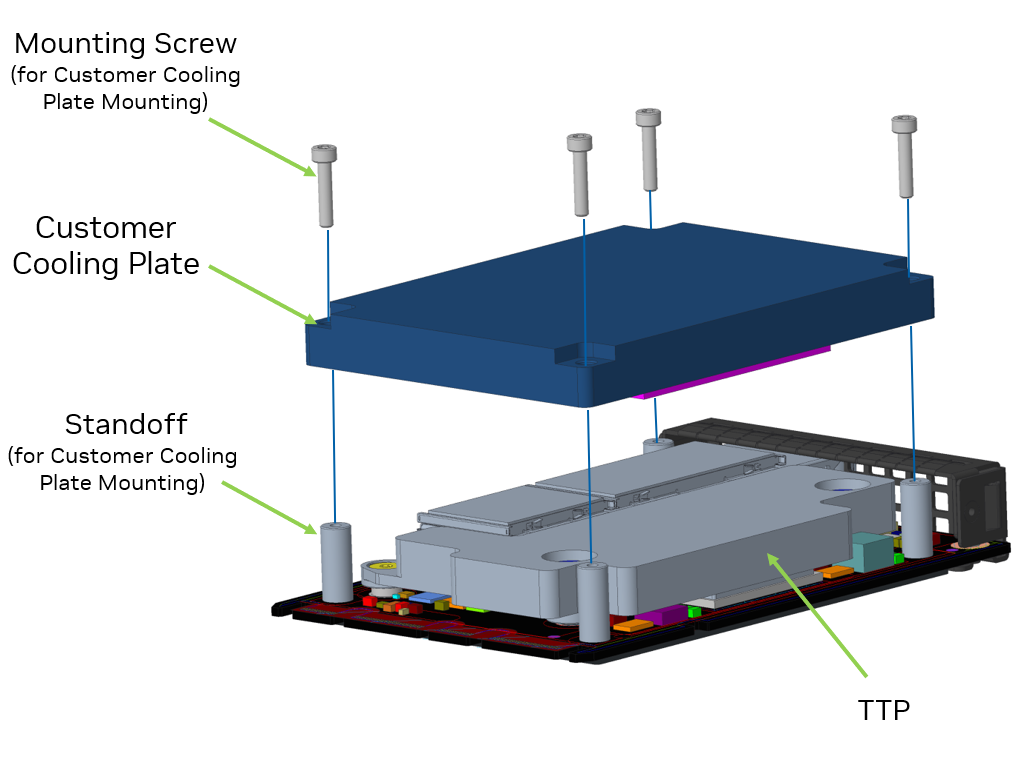

Recommended torque values for the customer cooling solution interface: M2.5: 0.44~0.46 Nm. Refer to the cooling mechanism documentation for the required torque.

It is the responsibility of the customer to ensure proper cooling and thermal regulation for all components on the board. The provided guidelines are minimal and are based on NVIDIA's air-cooling thermal solution.

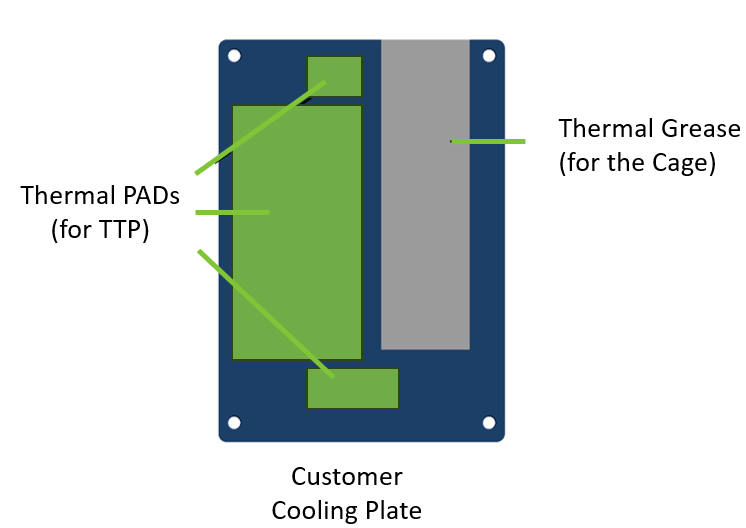

There are two components that require cooling, the built-in TTP and the networking port cage.

TTP

The SuperNIC IC is in contact with the built-in TTP on the component side of the product.

The maximum allowed force applied on the TTP should adhere to the following specifications:

268 Newtons on the TTP (max thermal pads area:2077mm^2)

Force should be spread equally on the TTP top surface.

Thermal Pad minimum allowable conductivity is 2.5 W/mK

Networking Cage

The thermal grease the comes in contact with the networking cage thermal bridge. Recommended thermal grease for the cage's thermal bridge is DOWSIL TC-5622 0.1+-0.05 mm thickness.

The four screws should be assembled from the customer cooling solution, through the four standoffs on the ConnectX-8 SuperNIC.

The four standoffs type is M2.5x0.45 thread and the maximum thread depth 4.0 mm.

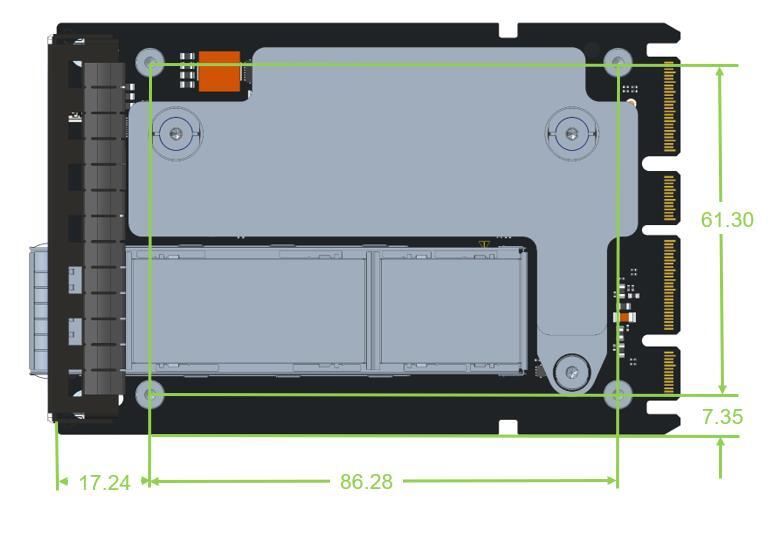

To ensure proper SuperNIC connectivity to the server and TTP, the below figure displays the SuperNIC threads and holes and provides its dimensions.