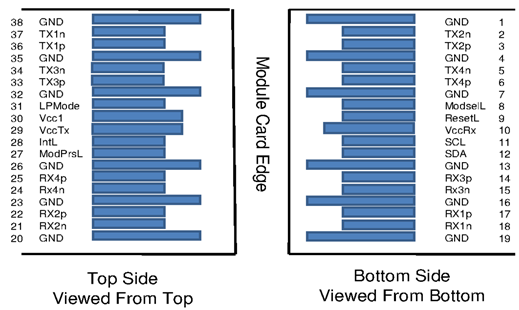

Pin Description

Pin | Symbol | Description | Pin | Symbol | Description |

1 | GND | Ground | 20 | GND | Ground |

2 | Tx2n | Transmitter Inverted Data Input | 21 | Rx2n | Receiver Inverted Data Output |

3 | Tx2p | Transmitter Non-Inverted Data Input | 22 | Rx2p | Receiver Non-Inverted Data Output |

4 | GND | Ground | 23 | GND | Grounds |

5 | Tx4n | Transmitter Inverted Data Input | 24 | Rx4n | Receiver Inverted Data Output |

6 | Tx4p | Transmitter Non-Inverted Data Input | 25 | Rx4p | Receiver Non-Inverted Data Output |

7 | GND | Ground | 26 | GND | Ground |

8 | ModSelL | Module Select | 27 | ModPrsL | Module Present |

9 | ResetL | Module Reset | 28 | IntL | Interrupt |

10 | Vcc Rx | +3.3V Power Supply Receiver | 29 | Vcc Tx | +3.3V Power Supply Transmitter |

11 | SCL | 2-wire Serial Interface Clock | 30 | Vcc1 | +3.3V Power Supply |

12 | SDA | 2-wire Serial Interface Data | 31 | LPMode | Low Power Mode |

13 | GND | GND | 32 | GND | Ground |

14 | Rx3p | Receiver Non-Inverted Data Output | 33 | Tx3p | Transmitter Non-Inverted Data Input |

15 | Rx3n | Receiver Inverted Data Output | 34 | Tx3n | Transmitter Inverted Data Input |

16 | GND | Ground | 35 | GND | Ground |

17 | Rx1p | Receiver Non-Inverted Data Output | 36 | Tx1p | Transmitter Non-Inverted Data Input |

18 | Rx1n | Receiver Inverted Data Output | 37 | Tx1n | Transmitter Inverted Data Input |

19 | GND | Ground | 38 | GND | Ground |

QSFP56 Module Pad Layout

The MMA1T00 transceiver is SFF-8636 compliant. This means that the control signals shown in the pad layout support the following functions:

ModPrsL | Module Present pin, grounded inside the module. Terminated with pull-up in the host system. Asserted low when the transceiver is inserted, whereby the host detects the presence of the transceiver. |

ModSelL | Module Select input pin, terminated high in the module. Only when held low by the host, the module responds to 2-wire serial communication commands. The ModSelL enables multiple modules to share a single 2-wire interface bus. |

ResetL | Reset input pin, pulled high in the module. A low level on the ResetL pin for longer than the minimum pulse length (t_Reset_init) initiates a complete module reset, returning all user module settings to their default state. During reset the host shall disregard all status bits until the module indicates completion of the reset interrupt by asserting IntL signal low with the Data_Not_Ready bit negated. Note that on power up (including hot insertion) the module completes the reset interrupt without requiring a reset. |

LPMode | Low Power Mode input, pulled up inside the module. The transceiver starts up in low power mode, i.e. <1.5 W with the two-wire interface active. The host system can read the power class declaration from the transceiver and determine if it has enough power to enable the high-speed operation/high power mode of the transceiver. This can be done by asserting LPMode low or by use of the Power_over-ride and Power_set control bits (Address A0h, byte 93 bits 0,1). |

IntL | Interrupt Low is an open-collector output, terminated high in the host system. A “Low” indicates a possible module operational fault or a status critical to the host system, e.g. temperature alarm. The host identifies the source of the interrupt using the 2-wire serial interface. The INTL pin is de-asserted “High” after completion of reset, when byte 2 bit 0 (Data Not Ready) is read with a value of ‘0’. |

The low-speed signals are Low Voltage TTL (LVTTL) compliant, except for SCL and SDA signals.

The transceiver can be damaged by exposure to current surges and over voltage events. Take care to restrict exposure to the conditions defined in Absolute Maximum Ratings. Observe normal handling precautions for electrostatic discharge-sensitive devices. The transceiver is shipped with dust caps on both the electrical and the optical port. The cap on the optical port should always be in place when there is no fiber cable connected. The optical connector has a recessed connector surface which is exposed whenever it has no cable nor cap.

Prior to insertion of the fiber cable, clean the cable connector to prevent contamination from it. The dust cap ensures that the optics remain clean and no additional cleaning should be needed. In the event of contamination, standard cleaning tools and methods should be used. Liquids must not be applied.