Conjugate Heat Transfer

This tutorial uses Modulus to study the conjugate heat transfer between the heat sink and the surrounding fluid. The temperature variations inside solid and fluid would be solved in a coupled manner with appropriate interface boundary conditions. In this tutorial, you will learn:

How to generate a 3D geometry using the geometry module in Modulus.

How to set up a conjugate heat transfer problem using the interface boundary conditions in Modulus.

How to use the Multi-Phase training approach in Modulus for one way coupled problems.

This tutorial assumes that you have completed tutorial Introductory Example on and have familiarized yourself with the basics of the Modulus APIs. Also, you should review the Scalar Transport: 2D Advection Diffusion tutorial for additional details on writing some of the thermal boundary conditions.

The scripts used in this problem can be found at examples/three_fin_3d/. The scripts are made configurable such that the same three fin problem can be solved for higher reynolds numbers,

parameterized geometry, etc. very easily by only configuring the Hydra configs. This example focuses on the laminar variant of this as the purpose of this tutorial is to cover

the ideas related to multi-phase training and conjugate heat transfer. The tutorial Parameterized 3D Heat Sink covers the parameterization aspect of this problem.

Therefore in this problem, the custom configs for turbulent and parameterized are both set to false.

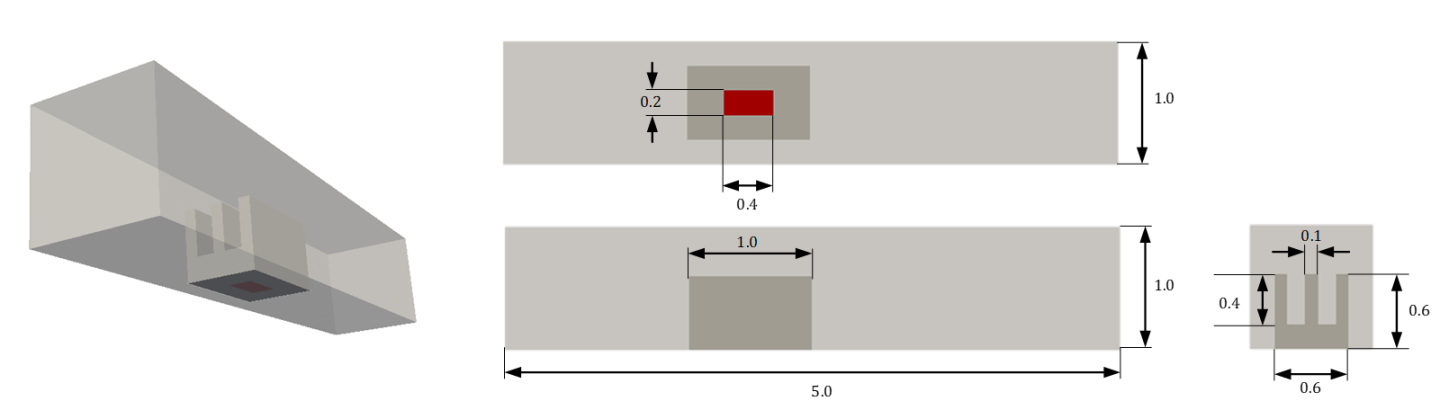

The geometry for a 3-fin heat sink placed inside a channel is shown in Fig. 142. The inlet to the channel is at 1 \(m/s\). The pressure at the outlet is specified as 0 \(Pa\). All the other surfaces of the geometry are treated as no-slip walls.

Fig. 142 Three fin heat sink geometry (All dimensions in \(m\))

The inlet is at 273.15 \(K\). The channel walls are adiabatic. The heat sink has a heat source of \(0.2 \times 0.4\) \(m\) at the bottom of the heat sink situated centrally on the bottom surface. The heat source generates heat such that the temperature gradient on the source surface is 360 \(K/m\) in the normal direction. Conjugate heat transfer takes place between the fluid-solid contact surface.

The properties fluid and thermal properties of the fluid and the solid are as follows:

Property |

Fluid |

Solid |

Kinematic Viscosity \((m^2/s)\) |

0.02 |

NA |

Thermal Diffusivity \((m^2/s)\) |

0.02 |

0.0625 |

Thermal Conductivity \((W/m.K)\) |

1.0 |

5.0 |

In this tutorial, since you are dealing with only incompressible flow, there is a one way coupling between the heat and flow equations. This means that it is possible to train the temperature field after the flow field is trained and converged. Such an approach is useful while training the multiphysics problems which are one way coupled as it is possible to achieve significant speed-up, as well as simulate cases with same flow boundary conditions but different thermal boundary conditions. One can easily use the same flow field as in input to train for different thermal boundary conditions.

Therefore, for this problem you have three separate files for the geometry,

flow solver, and heat solver. The three_fin_geometry.py will contain

all the definitions of geometry. three_fin_flow.py and three_fin_thermal.py

would then use this geometry to setup the relevant flow and heat constraints and

solve them individually. The basic idea would be to train the flow model to convergence

and then start the heat training after by initializing from the trained flow model to solve

for the temperature distributions in fluid and solid simultaneously.

In this problem you will nondimensionalize the temperature according to the following equation:

(207)\[\theta= T/273.15 - 1.0\]

Creating Geometry

The three_fin_geometry.py script contains all the details relevant to the geometry generation.

We will use the Box primitive to create the

3-fin geometry and Channel primitive to generate the channel.

Similar to 2D, Channel and Box are defined by using the two

corner points. Like 2D, the Channel geometry has no bounding planes

in the x-direction. You will also make use of the repeat method to

create the fins. This speeds up the generation of repetitive

structures in comparison to constructing the same geometry separately and doing boolean operations to assemble them.

Use the Plane geometry to create the planes at the inlet and

outlet. The code for generating the required geometries is shown below.

Please note the normal directions for the inlet and outlet planes.

Additionally, the parameters required for solving the heat part as also defined upfront, ex. dimensions and locations of source etc.

The script contains a few extra definitions that are only relevant for parameterized geometry. These are not relevant for this tutorial.

# geometry params for domain

channel_origin = (-2.5, -0.5, -0.5)

channel_dim = (5.0, 1.0, 1.0)

heat_sink_base_origin = (-1.0, -0.5, -0.3)

heat_sink_base_dim = (1.0, 0.2, 0.6)

fin_origin = (heat_sink_base_origin[0] + 0.5 - fin_length_s / 2, -0.3, -0.3)

fin_dim = (fin_length_s, fin_height_s, fin_thickness_s) # two side fins

total_fins = 2 # two side fins

flow_box_origin = (-1.1, -0.5, -0.5)

flow_box_dim = (1.6, 1.0, 1.0)

source_origin = (-0.7, -0.5, -0.1)

source_dim = (0.4, 0.0, 0.2)

source_area = 0.08

# define geometry

class ThreeFin(object):

def __init__(self, parameterized: bool = False):

# set param ranges

if parameterized:

pr = Parameterization(param_ranges)

self.pr = param_ranges

else:

pr = Parameterization(fixed_param_ranges)

self.pr = fixed_param_ranges

# channel

self.channel = Channel(

channel_origin,

(

channel_origin[0] + channel_dim[0],

channel_origin[1] + channel_dim[1],

channel_origin[2] + channel_dim[2],

),

parameterization=pr,

)

# three fin heat sink

heat_sink_base = Box(

heat_sink_base_origin,

(

heat_sink_base_origin[0] + heat_sink_base_dim[0], # base of heat sink

heat_sink_base_origin[1] + heat_sink_base_dim[1],

heat_sink_base_origin[2] + heat_sink_base_dim[2],

),

parameterization=pr,

)

fin_center = (

fin_origin[0] + fin_dim[0] / 2,

fin_origin[1] + fin_dim[1] / 2,

fin_origin[2] + fin_dim[2] / 2,

)

fin = Box(

fin_origin,

(

fin_origin[0] + fin_dim[0],

fin_origin[1] + fin_dim[1],

fin_origin[2] + fin_dim[2],

),

parameterization=pr,

)

gap = (heat_sink_base_dim[2] - fin_dim[2]) / (

total_fins - 1

) # gap between fins

fin_2 = fin.translate([0, 0, gap])

fin = fin + fin_2

three_fin = heat_sink_base + fin

# parameterized center fin

center_fin_origin = (

heat_sink_base_origin[0] + 0.5 - fin_length_m / 2,

fin_origin[1],

-fin_thickness_m / 2,

)

center_fin_dim = (fin_length_m, fin_height_m, fin_thickness_m)

center_fin = Box(

center_fin_origin,

(

center_fin_origin[0] + center_fin_dim[0],

center_fin_origin[1] + center_fin_dim[1],

center_fin_origin[2] + center_fin_dim[2],

),

parameterization=pr,

)

self.three_fin = three_fin + center_fin

# entire geometry

self.geo = self.channel - self.three_fin

# low and high resultion geo away and near the heat sink

flow_box = Box(

flow_box_origin,

(

flow_box_origin[0] + flow_box_dim[0], # base of heat sink

flow_box_origin[1] + flow_box_dim[1],

flow_box_origin[2] + flow_box_dim[2],

),

)

self.lr_geo = self.geo - flow_box

self.hr_geo = self.geo & flow_box

lr_bounds_x = (channel_origin[0], channel_origin[0] + channel_dim[0])

lr_bounds_y = (channel_origin[1], channel_origin[1] + channel_dim[1])

lr_bounds_z = (channel_origin[2], channel_origin[2] + channel_dim[2])

self.lr_bounds = {x: lr_bounds_x, y: lr_bounds_y, z: lr_bounds_z}

hr_bounds_x = (flow_box_origin[0], flow_box_origin[0] + flow_box_dim[0])

hr_bounds_y = (flow_box_origin[1], flow_box_origin[1] + flow_box_dim[1])

hr_bounds_z = (flow_box_origin[2], flow_box_origin[2] + flow_box_dim[2])

self.hr_bounds = {x: hr_bounds_x, y: hr_bounds_y, z: hr_bounds_z}

# inlet and outlet

self.inlet = Plane(

channel_origin,

(

channel_origin[0],

channel_origin[1] + channel_dim[1],

channel_origin[2] + channel_dim[2],

),

-1,

parameterization=pr,

)

self.outlet = Plane(

(channel_origin[0] + channel_dim[0], channel_origin[1], channel_origin[2]),

(

channel_origin[0] + channel_dim[0],

channel_origin[1] + channel_dim[1],

channel_origin[2] + channel_dim[2],

),

1,

parameterization=pr,

)

# planes for integral continuity

self.integral_plane = Plane(

(x_pos, channel_origin[1], channel_origin[2]),

(

x_pos,

channel_origin[1] + channel_dim[1],

channel_origin[2] + channel_dim[2],

),

1,

)

Neural network, Nodes and Multi-Phase training

Let’s have a look at the networks and nodes required to solve the flow and heat for this problem. The architectures and nodes for flow problem are very similar to previous tutorials. You will add the nodes for NavierStokes and NormalDotVec and create a single flow network that has the coordinates as inputs and the velocity components and the pressure as output. The code for the flow nodes can be found here:

# make navier stokes equations

if cfg.custom.turbulent:

ze = ZeroEquation(nu=0.002, dim=3, time=False, max_distance=0.5)

ns = NavierStokes(nu=ze.equations["nu"], rho=1.0, dim=3, time=False)

navier_stokes_nodes = ns.make_nodes() + ze.make_nodes()

else:

ns = NavierStokes(nu=0.01, rho=1.0, dim=3, time=False)

navier_stokes_nodes = ns.make_nodes()

normal_dot_vel = NormalDotVec()

# make network arch

if cfg.custom.parameterized:

input_keys = [

Key("x"),

Key("y"),

Key("z"),

Key("fin_height_m"),

Key("fin_height_s"),

Key("fin_length_m"),

Key("fin_length_s"),

Key("fin_thickness_m"),

Key("fin_thickness_s"),

]

else:

input_keys = [Key("x"), Key("y"), Key("z")]

flow_net = FullyConnectedArch(

input_keys=input_keys, output_keys=[Key("u"), Key("v"), Key("w"), Key("p")]

)

# make list of nodes to unroll graph on

flow_nodes = (

navier_stokes_nodes

+ normal_dot_vel.make_nodes()

+ [flow_net.make_node(name="flow_network")]

)

For the thermal nodes, start by adding nodes for relevant equations like AdvectionDiffusion, Diffusion, DiffusionInterface and GradNormal that will be used to define the various thermal boundary conditions relevant to this problem. Also, create 3 separate neural networks flow_net, thermal_f_net and thermal_s_net. The first one is the same flow network defined in the flow scripts. This network architecture definition in heat script must exactly match to that of the flow script for successful initialization of the flow model during heat training. Set the optimize argument as False while making the nodes of flow network to avoid optimizing the flow network during the heat training. Finally, separate networks to predict the temperatures in fluid and solid are created.

# make thermal equations

ad = AdvectionDiffusion(T="theta_f", rho=1.0, D=0.02, dim=3, time=False)

dif = Diffusion(T="theta_s", D=0.0625, dim=3, time=False)

dif_inteface = DiffusionInterface("theta_f", "theta_s", 1.0, 5.0, dim=3, time=False)

f_grad = GradNormal("theta_f", dim=3, time=False)

s_grad = GradNormal("theta_s", dim=3, time=False)

# make network arch

if cfg.custom.parameterized:

input_keys = [

Key("x"),

Key("y"),

Key("z"),

Key("fin_height_m"),

Key("fin_height_s"),

Key("fin_length_m"),

Key("fin_length_s"),

Key("fin_thickness_m"),

Key("fin_thickness_s"),

]

else:

input_keys = [Key("x"), Key("y"), Key("z")]

flow_net = FullyConnectedArch(

input_keys=input_keys,

output_keys=[Key("u"), Key("v"), Key("w"), Key("p")],

)

thermal_f_net = FullyConnectedArch(

input_keys=input_keys, output_keys=[Key("theta_f")]

)

thermal_s_net = FullyConnectedArch(

input_keys=input_keys, output_keys=[Key("theta_s")]

)

# make list of nodes to unroll graph on

thermal_nodes = (

ad.make_nodes()

+ dif.make_nodes()

+ dif_inteface.make_nodes()

+ f_grad.make_nodes()

+ s_grad.make_nodes()

+ [flow_net.make_node(name="flow_network", optimize=False)]

+ [thermal_f_net.make_node(name="thermal_f_network")]

+ [thermal_s_net.make_node(name="thermal_s_network")]

)

Setting up Flow Domain and Constraints

The contents of three_fin_flow.py script are described below.

Inlet, Outlet and Channel and Heat Sink walls

For inlet boundary conditions, specify the velocity to be a constant velocity of 1.0 \(m/s\) in x-direction. Like in tutorial Introductory Example, weight the velocity by the SDF of the channel to avoid sharp discontinuity at the boundaries. For outlet, specify the pressure to be 0. All the channel walls and heat sink walls are treated as no slip boundaries.

Interior

The flow equations can be specified in the low resolution and high

resolution domains of the problem by using PointwiseInteriorConstraint. This allows

independent point densities in these two areas to be controlled easily.

Integral Continuity

The inlet volumetric flow is 1 \(m^3/s\) so,

specify 1.0 as the value for integral_continuity key.

The code for flow domain is shown below.

# make flow domain

flow_domain = Domain()

# inlet

u_profile = inlet_vel * tanh((0.5 - Abs(y)) / 0.02) * tanh((0.5 - Abs(z)) / 0.02)

constraint_inlet = PointwiseBoundaryConstraint(

nodes=flow_nodes,

geometry=geo.inlet,

outvar={"u": u_profile, "v": 0, "w": 0},

batch_size=cfg.batch_size.Inlet,

criteria=Eq(x, channel_origin[0]),

lambda_weighting={

"u": 1.0,

"v": 1.0,

"w": 1.0,

}, # weight zero on edges

parameterization=geo.pr,

batch_per_epoch=5000,

)

flow_domain.add_constraint(constraint_inlet, "inlet")

# outlet

constraint_outlet = PointwiseBoundaryConstraint(

nodes=flow_nodes,

geometry=geo.outlet,

outvar={"p": 0},

batch_size=cfg.batch_size.Outlet,

criteria=Eq(x, channel_origin[0] + channel_dim[0]),

lambda_weighting={"p": 1.0},

parameterization=geo.pr,

batch_per_epoch=5000,

)

flow_domain.add_constraint(constraint_outlet, "outlet")

# no slip for channel walls

no_slip = PointwiseBoundaryConstraint(

nodes=flow_nodes,

geometry=geo.geo,

outvar={"u": 0, "v": 0, "w": 0},

batch_size=cfg.batch_size.NoSlip,

lambda_weighting={

"u": 1.0,

"v": 1.0,

"w": 1.0,

}, # weight zero on edges

parameterization=geo.pr,

batch_per_epoch=5000,

)

flow_domain.add_constraint(no_slip, "no_slip")

# flow interior low res away from three fin

lr_interior = PointwiseInteriorConstraint(

nodes=flow_nodes,

geometry=geo.geo,

outvar={"continuity": 0, "momentum_x": 0, "momentum_y": 0, "momentum_z": 0},

batch_size=cfg.batch_size.InteriorLR,

lambda_weighting={

"continuity": Symbol("sdf"),

"momentum_x": Symbol("sdf"),

"momentum_y": Symbol("sdf"),

"momentum_z": Symbol("sdf"),

},

compute_sdf_derivatives=True,

parameterization=geo.pr,

batch_per_epoch=5000,

criteria=Or(x < -1.1, x > 0.5),

)

flow_domain.add_constraint(lr_interior, "lr_interior")

# flow interiror high res near three fin

hr_interior = PointwiseInteriorConstraint(

nodes=flow_nodes,

geometry=geo.geo,

outvar={"continuity": 0, "momentum_x": 0, "momentum_z": 0, "momentum_y": 0},

batch_size=cfg.batch_size.InteriorLR,

lambda_weighting={

"continuity": Symbol("sdf"),

"momentum_x": Symbol("sdf"),

"momentum_y": Symbol("sdf"),

"momentum_z": Symbol("sdf"),

},

compute_sdf_derivatives=True,

parameterization=geo.pr,

batch_per_epoch=5000,

criteria=And(x > -1.1, x < 0.5),

)

flow_domain.add_constraint(hr_interior, "hr_interior")

# integral continuity

def integral_criteria(invar, params):

sdf = geo.geo.sdf(invar, params)

return np.greater(sdf["sdf"], 0)

integral_continuity = IntegralBoundaryConstraint(

nodes=flow_nodes,

geometry=geo.integral_plane,

outvar={"normal_dot_vel": volumetric_flow},

batch_size=5,

integral_batch_size=cfg.batch_size.IntegralContinuity,

criteria=integral_criteria,

lambda_weighting={"normal_dot_vel": 1.0},

parameterization={**geo.pr, **{x_pos: (-1.1, 0.1)}},

fixed_dataset=False,

num_workers=4,

)

flow_domain.add_constraint(integral_continuity, "integral_continuity")

The addition of integral continuity planes and separate flow box for dense sampling are examples of adding more training data and user knowledge/bias of the problem to the training. This addition helps to improve the accuracy and convergence to a great extent and it is recommended wherever possible.

Setting up Thermal Multi-Phase Domain and Constraints

The contents of three_fin_thermal.py are described below.

Inlet, Outlet and Channel walls:

For the heat part, specify temperature at the inlet. All the

outlet and the channel walls will have a zero gradient boundary

condition which will be enforced by setting

'normal_gradient_theta_f' equal to 0. We will use 'theta_f' for

defining the temperatures in fluid and 'theta_s' for defining the

temperatures in solid.

Fluid and Solid Interior:

Just like the Scalar Transport: 2D Advection Diffusion tutorial,

set 'advection_diffusion' equal to 0 in both, low and high

resolution fluid domains. For solid interior, set

'diffusion' equal to 0.

Fluid-Solid Interface:

For the interface between fluid and solid, enforce both Neumann

and Dirichlet boundary condition by setting

'diffusion_interface_dirichlet_theta_f_theta_s' and

'diffusion_interface_neumann_theta_f_theta_s' both equal to 0.

The order in which you define 'theta_f' and 'theta_s' in the interface boundary condition must match the one in PDE definition DiffusionInterface to avoid any graph unroll errors.

The corresponding conductivities must be also specified in the same order in the PDE definition.

Heat Source:

Apply a \(tanh\) smoothing while defining the heat source on

the bottom wall of the heat sink. Smoothing out the

sharp boundaries helps in training the Neural Network converge faster.

The 'normal_gradient_theta_s' is set equal to grad_t in the area

of source and 0 everywhere else on the bottom surface of heat sink.

The code for heat domain is shown below.

# make flow domain

thermal_domain = Domain()

# inlet

constraint_inlet = PointwiseBoundaryConstraint(

nodes=thermal_nodes,

geometry=geo.inlet,

outvar={"theta_f": inlet_t},

batch_size=cfg.batch_size.Inlet,

criteria=Eq(x, channel_origin[0]),

lambda_weighting={"theta_f": 1.0}, # weight zero on edges

parameterization=geo.pr,

)

thermal_domain.add_constraint(constraint_inlet, "inlet")

# outlet

constraint_outlet = PointwiseBoundaryConstraint(

nodes=thermal_nodes,

geometry=geo.outlet,

outvar={"normal_gradient_theta_f": 0},

batch_size=cfg.batch_size.Outlet,

criteria=Eq(x, channel_origin[0] + channel_dim[0]),

lambda_weighting={"normal_gradient_theta_f": 1.0}, # weight zero on edges

parameterization=geo.pr,

)

thermal_domain.add_constraint(constraint_outlet, "outlet")

# channel walls insulating

def wall_criteria(invar, params):

sdf = geo.three_fin.sdf(invar, params)

return np.less(sdf["sdf"], -1e-5)

channel_walls = PointwiseBoundaryConstraint(

nodes=thermal_nodes,

geometry=geo.channel,

outvar={"normal_gradient_theta_f": 0},

batch_size=cfg.batch_size.ChannelWalls,

criteria=wall_criteria,

lambda_weighting={"normal_gradient_theta_f": 1.0},

parameterization=geo.pr,

)

thermal_domain.add_constraint(channel_walls, "channel_walls")

# fluid solid interface

def interface_criteria(invar, params):

sdf = geo.channel.sdf(invar, params)

return np.greater(sdf["sdf"], 0)

fluid_solid_interface = PointwiseBoundaryConstraint(

nodes=thermal_nodes,

geometry=geo.three_fin,

outvar={

"diffusion_interface_dirichlet_theta_f_theta_s": 0,

"diffusion_interface_neumann_theta_f_theta_s": 0,

},

batch_size=cfg.batch_size.SolidInterface,

criteria=interface_criteria,

parameterization=geo.pr,

)

thermal_domain.add_constraint(fluid_solid_interface, "fluid_solid_interface")

# heat source

sharpen_tanh = 60.0

source_func_xl = (tanh(sharpen_tanh * (x - source_origin[0])) + 1.0) / 2.0

source_func_xh = (

tanh(sharpen_tanh * ((source_origin[0] + source_dim[0]) - x)) + 1.0

) / 2.0

source_func_zl = (tanh(sharpen_tanh * (z - source_origin[2])) + 1.0) / 2.0

source_func_zh = (

tanh(sharpen_tanh * ((source_origin[2] + source_dim[2]) - z)) + 1.0

) / 2.0

gradient_normal = (

grad_t * source_func_xl * source_func_xh * source_func_zl * source_func_zh

)

heat_source = PointwiseBoundaryConstraint(

nodes=thermal_nodes,

geometry=geo.three_fin,

outvar={"normal_gradient_theta_s": gradient_normal},

batch_size=cfg.batch_size.HeatSource,

criteria=Eq(y, source_origin[1]),

)

thermal_domain.add_constraint(heat_source, "heat_source")

# flow interior low res away from three fin

lr_flow_interior = PointwiseInteriorConstraint(

nodes=thermal_nodes,

geometry=geo.geo,

outvar={"advection_diffusion_theta_f": 0},

batch_size=cfg.batch_size.InteriorLR,

criteria=Or(x < -1.1, x > 0.5),

)

thermal_domain.add_constraint(lr_flow_interior, "lr_flow_interior")

# flow interiror high res near three fin

hr_flow_interior = PointwiseInteriorConstraint(

nodes=thermal_nodes,

geometry=geo.geo,

outvar={"advection_diffusion_theta_f": 0},

batch_size=cfg.batch_size.InteriorHR,

criteria=And(x > -1.1, x < 0.5),

)

thermal_domain.add_constraint(hr_flow_interior, "hr_flow_interior")

# solid interior

solid_interior = PointwiseInteriorConstraint(

nodes=thermal_nodes,

geometry=geo.three_fin,

outvar={"diffusion_theta_s": 0},

batch_size=cfg.batch_size.SolidInterior,

lambda_weighting={"diffusion_theta_s": 100.0},

)

thermal_domain.add_constraint(solid_interior, "solid_interior")

Adding Validators and Monitors

In this tutorial you will monitors for pressure drops during the flow field simulation and monitors for peak temperature reached in the source chip during the heat simulation.

Similarly, respective validation data are added to the flow and heat scripts. Only flow monitors and validators are shown for brevity.

Monitors and validators in flow script:

# flow data

mapping = {

"Points:0": "x",

"Points:1": "y",

"Points:2": "z",

"U:0": "u",

"U:1": "v",

"U:2": "w",

"p_rgh": "p",

}

if cfg.custom.turbulent:

openfoam_var = csv_to_dict(

to_absolute_path("openfoam/threeFin_extend_zeroEq_re500_fluid.csv"), mapping

)

else:

openfoam_var = csv_to_dict(

to_absolute_path("openfoam/threeFin_extend_fluid0.csv"), mapping

)

openfoam_var = {key: value[0::4] for key, value in openfoam_var.items()}

openfoam_var["x"] = openfoam_var["x"] + channel_origin[0]

openfoam_var["y"] = openfoam_var["y"] + channel_origin[1]

openfoam_var["z"] = openfoam_var["z"] + channel_origin[2]

openfoam_var.update({"fin_height_m": np.full_like(openfoam_var["x"], 0.4)})

openfoam_var.update({"fin_height_s": np.full_like(openfoam_var["x"], 0.4)})

openfoam_var.update({"fin_thickness_m": np.full_like(openfoam_var["x"], 0.1)})

openfoam_var.update({"fin_thickness_s": np.full_like(openfoam_var["x"], 0.1)})

openfoam_var.update({"fin_length_m": np.full_like(openfoam_var["x"], 1.0)})

openfoam_var.update({"fin_length_s": np.full_like(openfoam_var["x"], 1.0)})

openfoam_invar_numpy = {

key: value

for key, value in openfoam_var.items()

if key

in [

"x",

"y",

"z",

"fin_height_m",

"fin_height_s",

"fin_thickness_m",

"fin_thickness_s",

"fin_length_m",

"fin_length_s",

]

}

openfoam_outvar_numpy = {

key: value for key, value in openfoam_var.items() if key in ["u", "v", "w", "p"]

}

openfoam_validator = PointwiseValidator(

nodes=flow_nodes,

invar=openfoam_invar_numpy,

true_outvar=openfoam_outvar_numpy,

)

flow_domain.add_validator(openfoam_validator)

# add pressure monitor

invar_inlet_pressure = geo.integral_plane.sample_boundary(

1024, parameterization={**fixed_param_ranges, **{x_pos: -2}}

)

pressure_monitor = PointwiseMonitor(

invar_inlet_pressure,

output_names=["p"],

metrics={"inlet_pressure": lambda var: torch.mean(var["p"])},

nodes=flow_nodes,

)

flow_domain.add_monitor(pressure_monitor)

Once both the flow and heat scripts are defined, run the

three_fin_flow.py first to solve for the flow field. Once a

desired level of convergence is achieved you can run three_fin_thermal.py to solve for heat.

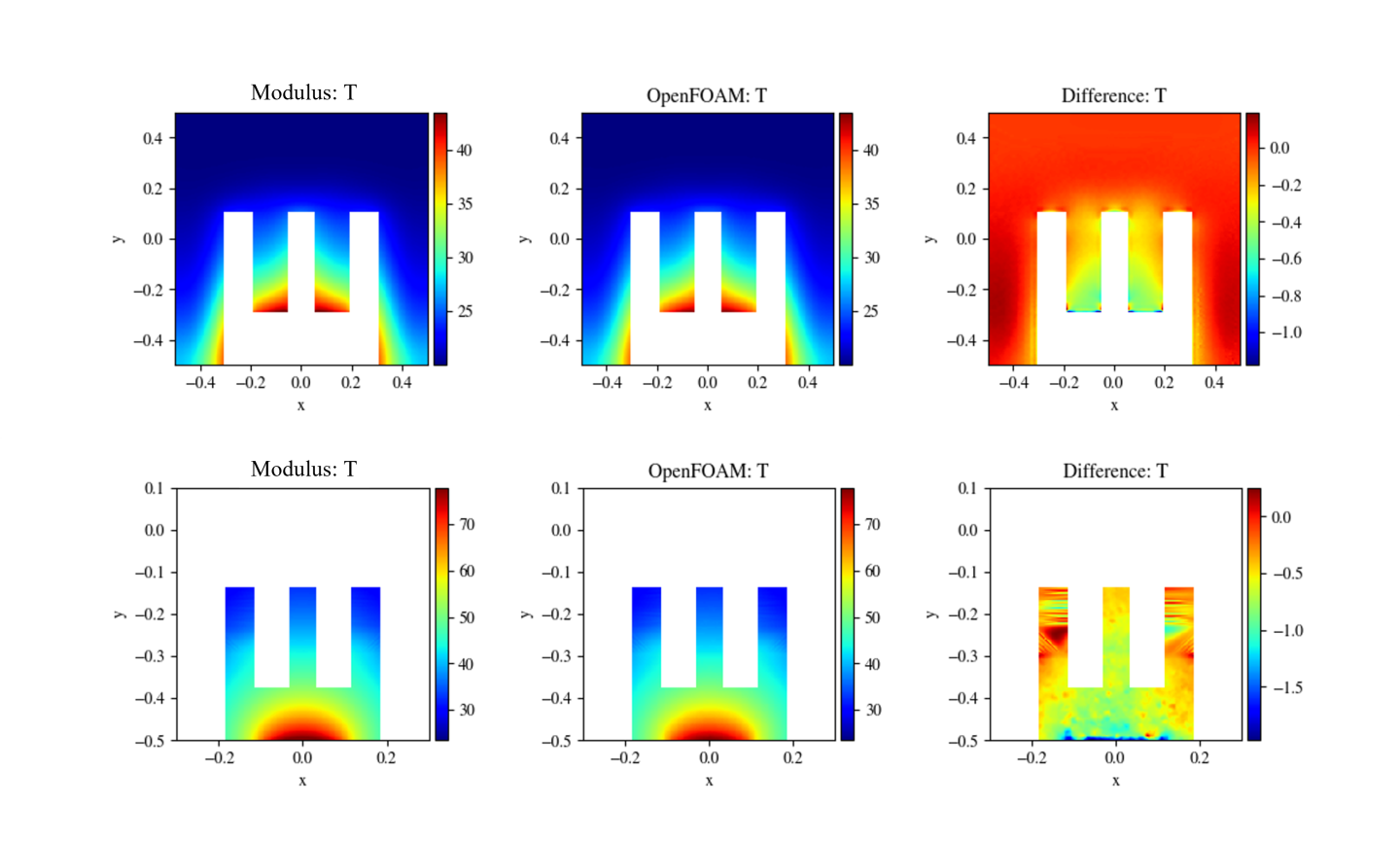

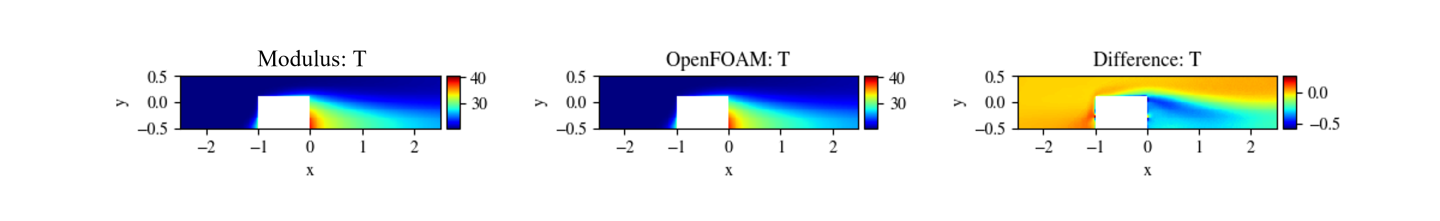

The table and figures below show the results of Pressure drop and Peak temperatures obtained from the Modulus and compare it with the results from OpenFOAM solver.

Modulus |

OpenFOAM |

|

Pressure Drop \((Pa)\) |

7.51 |

7.49 |

Peak Temperature \((^{\circ} C)\) |

78.35 |

78.05 |

Fig. 143 Left: Modulus. Center: OpenFOAM. Right: Difference. Top: Temperature distribution in Fluid. Bottom: Temperature distribution in Solid (Temperature scales in C)

Fig. 144 Left: Modulus. Center: OpenFOAM. Right: Difference. (Temperature scales in C)

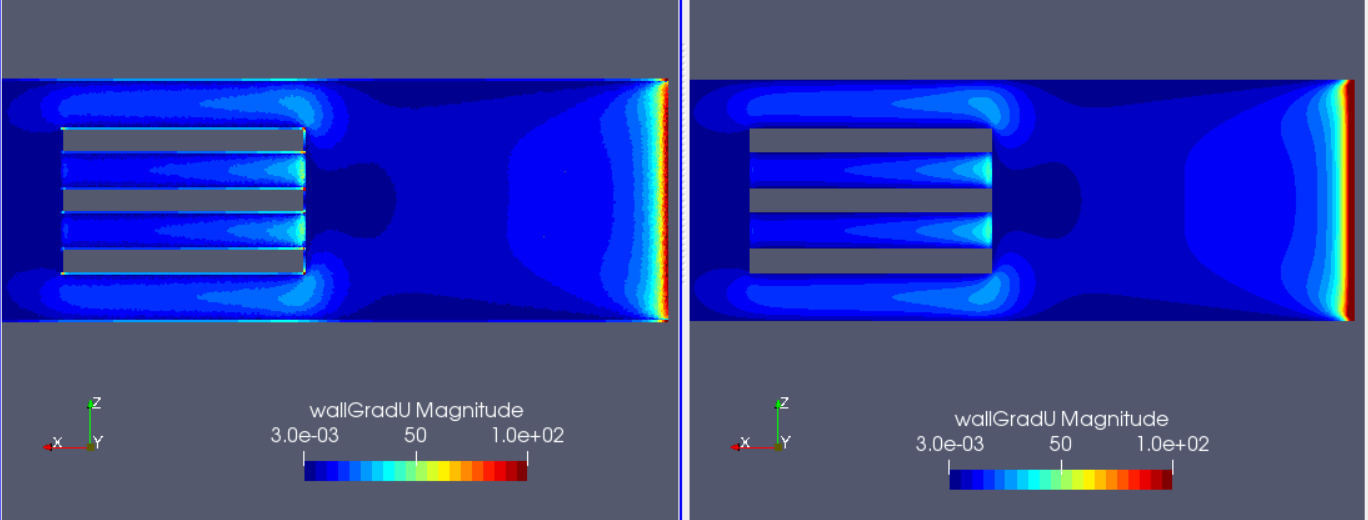

Plotting gradient quantities: Wall Velocity Gradients

In a variety of applications, it is desirable to plot the gradients of

some quantities inside the domain. One such example relevant to fluid

flows is the wall velocity gradients and wall shear stresses. These

quantities are often plotted to compute frictional forces, etc. You can

visualize such quantities in Modulus by outputting the \(x\),

\(y\) and \(z\) derivatives of the desired variables using an

PointwiseInferencer.

...

# add inferencer

inferencer = PointwiseInferencer(

geo.sample_boundary(4000, parameterization=pr),

["u__x", "u__y", "u__z",

"v__x", "v__y", "v__z",

"w__x", "w__y", "w__z"],

nodes=flow_nodes,

)

flow_domain.add_inferencer(inferencer, "inf_data")

You can then post-process these quantities based on your choice to visualize the desired variables. Paraview’s Calculator Filter was used for the plot shown below. The wall velocity gradients comparison between OpenFOAM and Modulus is shown in Fig. 145.

Fig. 145 Comparison of magnitude of wall velocity gradients. Left: Modulus. Right: OpenFOAM